Benchtalk

Barrel Swapping

Gem from the forums past.

Tom Hencken: When you guys switch barrels on your bench guns, what lube do you use on the threads? How tight?

David J Halblom Sr: I use Permatex silver anti-sieze, the stuf that is almost impossible to wipe off your hands. As to torque, as tight as I can turn it w/o slipping in the barrel vise.

Al Nyhus: Hi Tom. I've used a few different lubes..moly paste (yuk), anti-seize, etc. and they all seem to work well. Lately, I've been using Permatex High Pressure Lube...but I don't think it really makes much difference as long as no lube gets between the face of the receiver and the recoil lug/barrel.

With all those new barrels you have for your 2 HBR guns, you should get J. up to speed on the barrel changing deal so she can be a-spinnin' 'em off left and right for 'ya! (big grin). See 'ya soon. -Al

Tom Hencken: Haven't heard from Stan yet and he's taken off a lot of barrels in this long life. Which is why the question is out there; the barrels have to come off! not just go on. And the lube should not creep anywhere it shouldn't be.

R.G. Robinett: Tom, I can't argue with what David H. and Al said - a little [of the various anti-seize compounds] goes a LONG way! Al's method of tightening is what Jonh Ambler advised Terry and I to do 25 years ago - it still works. RG

Jon Leu: When you say you tighten the barrel up to the receiver then back it off 1/8th of a turn then give it a "good hard snap," are you using your hand or an action wrench to give it the snap?

When I was shooting before, which was more than 20 years ago, I was in the habit of snapping the barrels on by hand. Even done by hand, it took a wrench and a vise to get them apart again.

jon

Stan Ware: Tom,

Let's talk about factory barrels first. Some times the Remington 700 come off hard and some people think that Remington uses a special lube or glue that hardens like Locktite. They do not..... they use a grease much like you would find in a grease gun. What happens is that then it goes to the bluing room and the Temp is 292 degrees and the salts will weep into the threads some. Now if the action and barrel are Chrome Moly bluing is a rust process and there in is part of the problem the barrel comes off hard. Then the gentleman who bought it installs his bases and thinking more is better puts a healthy dose of wicking Locktite on the screws and it wicks into the threads of the receiver.

That's why factory barrels come off hard. I have taken some off that had so much Locktite on them it was into the lug area. The front screw of the front base is the culprit. Be sure not to use a over abundance of any locking material on it.I sometimes remove the front base and squirt some Croil in the hole. It only takes a short time to work and makes things easier coming off.

Now we have the barrel off and have cleaned the threads up on the bbl and receiver and are going to put the same barrel back on with a action wrench. I am talking the T handle type that slides into the raceway and handles are about18 inches long. First you can put a small amount of lube of your choice on the threads and face of the receiver. I put some on the recoil lug also. What you will find is that when you get the action where it hits the barrel and insert your wrench that you have a whole bunch of sponge b/4 its comes to a stop. That is because the action is not true and in some cases the barrel may not be either. In other words the receiver is hitting the barrel shoulder at some point first and NOT all the way around and you are setting things up for stress on the receiver. This is why actions are trued. That way when the two surfaces hit its all the way around and not at just one point.

Now lets move to bench rest actions and barrels made of stainless steel. Stainless will gall in a heartbeat. There must be some slop in the thread for the receiver to self center on the barrel. The type of grease used should be a good grade of Moly based or Never Seize. You don't need a lot of it but some on the threads and faces of things that mate up. Now when you hand tighten the receiver up to the barrel you will find it goes bang and is tight... no sponge. At that point insert your wrench and I believe the method that Al and Randy talked about is the best way to tighten the barrel on. Some people use a torque wrench and tighten to so many inch pounds. That's all fine, but in my humble opinion it is not needed. I have seen that done on action screws also or some indicate or mark them so they get in the same place each time. My opinion of that is if you have a good bed job and NO rock it will tighten up just like the action that is trued, NO SPONGE.

In closing they make two different kinds of Locktite... wicking and not wicking. I use the none wicking type on the front screw. The other thing I need to ask is what did you mean Tom when you said....... "in Stan's long life" Are you saying I am getting OLD ? I know the truth hurts.... Suz don't even buy me green bananas any more.

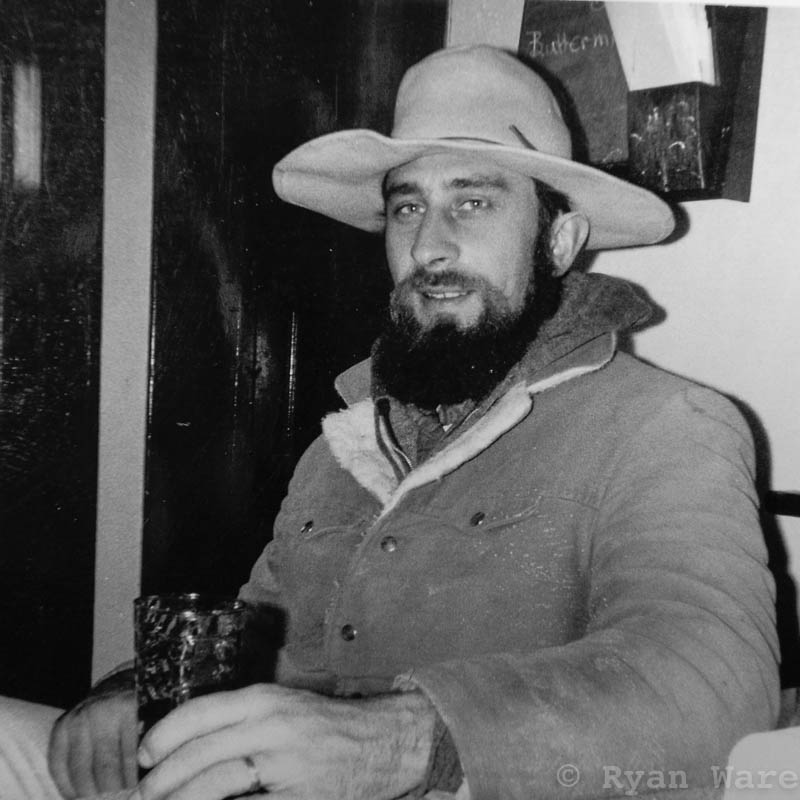

Stan

jim mckinnie: Hi fellas,The latest trend in Aussieland seems to be Nulon assembly paste for both the barrel thread & the locking lugs.

Is there any need to have a different lube when the receiver is Cr moly or stainless? All my barrels are stainless & my receivers are Cr moly.I really don't want to gall the lugs on my new action.

Thanks guys Jim

David J Halblom Sr: You just need to make sure you use a lube ALL the time. I like the Permatex because I have use it FOREVER, since building my first race engine at 14 yrs old

R.G. Robinett: Jon, Mr. Ambler advised Terry and I to use a "light" snap, using the action-wrench - as Al stated, about 1/8th turn is plenty. BUt, a square tenon shoulder against a square action-face will lock-up nicely by hand - I just like the "insurance" of a light/short snap. RG